Gear

Ratios

In

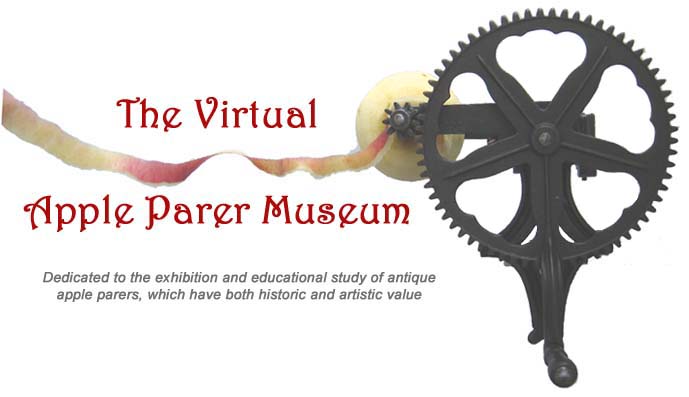

this inverted Reading (left) a larger hand-driven gear meshes with

a smaller gear turning the fork, which provides a speed advantage.

With one turn

of the hand-driven gear, the fork and apple rotate many times. One

can determine just how many times by calculating the gear ratio.

The gear

ratio can be determined by counting the teeth on the gears. In this

case, the hand-driven gear has 55 teeth and the fork gear has 17.

Divide 55 by 17 and you can see the apple will rotate 3.2 times

for every

complete turn of the hand-driven gear. In

this inverted Reading (left) a larger hand-driven gear meshes with

a smaller gear turning the fork, which provides a speed advantage.

With one turn

of the hand-driven gear, the fork and apple rotate many times. One

can determine just how many times by calculating the gear ratio.

The gear

ratio can be determined by counting the teeth on the gears. In this

case, the hand-driven gear has 55 teeth and the fork gear has 17.

Divide 55 by 17 and you can see the apple will rotate 3.2 times

for every

complete turn of the hand-driven gear.

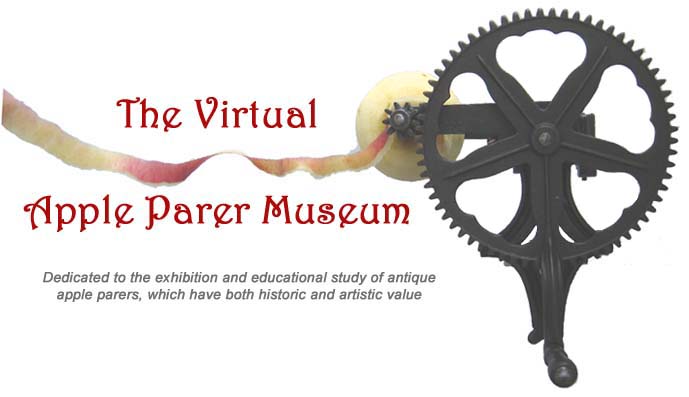

In

this same parer a steel axle connects the hand-driven gear to a smaller

table gear (pictured to the right). Even though the two gears are of

different size they rotate at the same rate because they are on the

same axle. The smaller table gear rotates

a larger

turntable gear, which provides a mechanical advantage. We can determine

how many times the hand-driven gear/shaft/table gear assembly must

be turned to rotate the turntable one time by calculating the gear ratio.

The turntable has 45 teeth and the small table gear rotating it

has 9 teeth. Divide 45 by 9 and we can see the small table gear

and hence the hand-driven gear must make 5 complete turns to rotate the

turntable once. So, roughly half of these 5 turns will be used to pare

the apple and the remaining turns used to place the paring blade back

into starting position. In

this same parer a steel axle connects the hand-driven gear to a smaller

table gear (pictured to the right). Even though the two gears are of

different size they rotate at the same rate because they are on the

same axle. The smaller table gear rotates

a larger

turntable gear, which provides a mechanical advantage. We can determine

how many times the hand-driven gear/shaft/table gear assembly must

be turned to rotate the turntable one time by calculating the gear ratio.

The turntable has 45 teeth and the small table gear rotating it

has 9 teeth. Divide 45 by 9 and we can see the small table gear

and hence the hand-driven gear must make 5 complete turns to rotate the

turntable once. So, roughly half of these 5 turns will be used to pare

the apple and the remaining turns used to place the paring blade back

into starting position.

The

axle of the small table gear is at a 90-degree angle from the

axle of the larger turntable gear. This gear arrangement is used

to change the direction of motion.

|