|

|

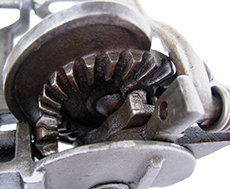

Helical

Gears

The

teeth of helical gears are at an angle to the axis of rotation. The teeth of the helical gear engage more slowly than those of spur

gears. The helical gear runs more smoothly. The Waverly (right) is

a quick return that uses helical gears on its returntable gear. The

teeth of helical gears are at an angle to the axis of rotation. The teeth of the helical gear engage more slowly than those of spur

gears. The helical gear runs more smoothly. The Waverly (right) is

a quick return that uses helical gears on its returntable gear.

The

Union makes the most creative use of helical gears. The outer edge of

the hand-driven gear is a spur gear that drives the fork spur gear; however,

the inside of the wheel is molded with long helical teeth, which interlock

with the center gear (left). The

outer edge of the center wheel is a bevel gear, but its inner surface is

graced with long helical teeth that mesh with the paring arm gear (below

left). Once an apple is pared the blade is pushed aside and the structure

of the long helical teeth are now oriented so as to cause the blade to

operate

in the reverse direction, allowing it to pare during the return motion. I must note that D. H. Whittemore refers to these structures as cams in his November 11, 1866 patent (US59,884). I like to think of them as a type of modified helical gear because of their orientation to one another. The

Union makes the most creative use of helical gears. The outer edge of

the hand-driven gear is a spur gear that drives the fork spur gear; however,

the inside of the wheel is molded with long helical teeth, which interlock

with the center gear (left). The

outer edge of the center wheel is a bevel gear, but its inner surface is

graced with long helical teeth that mesh with the paring arm gear (below

left). Once an apple is pared the blade is pushed aside and the structure

of the long helical teeth are now oriented so as to cause the blade to

operate

in the reverse direction, allowing it to pare during the return motion. I must note that D. H. Whittemore refers to these structures as cams in his November 11, 1866 patent (US59,884). I like to think of them as a type of modified helical gear because of their orientation to one another.

|