|

|

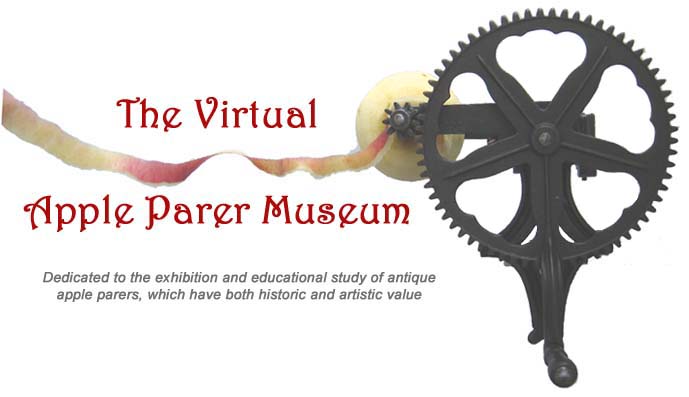

Bevel

Gears

Bevel

gears have a slight conical shape and are used in apple parers

to change the direction of motion. The small table gears and the

turntable

gears as illustrated by the Keyes (to the right) that rotate paring

arms are good examples. The slight conical shape of bevel gears

allows

them

to

work only on

axles

positioned

at angles greater than 0 or less

than 180-degrees. Bevel

gears have a slight conical shape and are used in apple parers

to change the direction of motion. The small table gears and the

turntable

gears as illustrated by the Keyes (to the right) that rotate paring

arms are good examples. The slight conical shape of bevel gears

allows

them

to

work only on

axles

positioned

at angles greater than 0 or less

than 180-degrees.

The

J.J. Parker (pictured to the left) uses a bevel gear to rotate the paring

arm 180-degrees. The S.S. Hersey (below) may have the most interesting

bevel gear

system. A small

bevel

gear sits

between two larger bevel gears at a 90-degree angle. The two larger bevel

gears rest on the same axle as the paring arm. On this axle, between

the two larger bevel gears, rests a smaller modified gear connected to

the paring arm. The paring arms modified gear has only two teeth, each

pointed

to the opposite bevel gear. The size of this centrally located gear with

two teeth allows it to only engage one of the larger bevel gears at a

time. The

J.J. Parker (pictured to the left) uses a bevel gear to rotate the paring

arm 180-degrees. The S.S. Hersey (below) may have the most interesting

bevel gear

system. A small

bevel

gear sits

between two larger bevel gears at a 90-degree angle. The two larger bevel

gears rest on the same axle as the paring arm. On this axle, between

the two larger bevel gears, rests a smaller modified gear connected to

the paring arm. The paring arms modified gear has only two teeth, each

pointed

to the opposite bevel gear. The size of this centrally located gear with

two teeth allows it to only engage one of the larger bevel gears at a

time.

As

one cranks the hand-driven gear the small bevel gear rotates the two

larger bevel gears in opposite directions. The paring arm follows the

direction of the large bevel gear that is engaged with its modified gear.

Once the paring action is completed a lever on the small bevel gear pushes

the paring arm’s modified gear across its axle to engage the opposite

bevel gear. After the gear switch, an apple can be pared in the reverse

direction. As

one cranks the hand-driven gear the small bevel gear rotates the two

larger bevel gears in opposite directions. The paring arm follows the

direction of the large bevel gear that is engaged with its modified gear.

Once the paring action is completed a lever on the small bevel gear pushes

the paring arm’s modified gear across its axle to engage the opposite

bevel gear. After the gear switch, an apple can be pared in the reverse

direction.

Visit Industrial Quick Search for a comprehensive article on bevel gears.

|